The effectiveness, cleanliness, and precision of packaging operations are critical to business success in the dynamic and highly managed food processing environment. In the case of sugar—whether fine granulated, powdered, or crystalline—hygiene standards and operational efficiency are equally dependent on choosing the correct sugar packaging machine. Minimized operational costs, pack-to-slice ratios, and consistent fill weights have become imperatives achieved only with advanced automated sugar packaging systems that effortlessly and accurately fulfill food safety standards and regulations while minimizing stop-and-go periods.

More and more companies today make use of the fully automated powder filling machine as part of an integrated approach to modern sugar packaging lines. These machines possess advanced capabilities where high precision and flexibility are programmable attributes. As a guide, these are the primary considerations that need to be prioritized in order to ensure a sugar packaging machine meets the demands of your production line.

Hygienic Design and Food Safety Compliance

Maintaining a hygienic production environment is one of the most critical aspects of a sugar packaging machine selection. As food-grade ingredients, sugar must be placed in packages processed in machines that have sanitary operations. Always check if the machine is constructed from food-grade stainless steel like SUS304 or SUS316, which do not rust and are easy to clean. Welds should be smooth, and surfaces void of grooves and gaps along with welded and sealed parts to prevent microbial contamination and sugar accumulation.

Machines must have FDA, CE, or GMP as food safety requirements in your country to operate. Having no tool access for cleaning, CIP units, and enclosures that do not permit dust to enter enhances sanitation standards and quicken maintenance. As much as ventilation and dust extraction need to be well-handled, airborne particles of sugar can create a safety and hygiene problem if not handled properly. Having a sugar packaging machine with these elements boosts compliance, mitigates recall events, and protects the company’s public image.

Precision Dosing, Fill Accuracy, Format Flexibility

In any packaging operation, having precise dosing is necessary to prevent product loss, ensure compliance, and maintain brand reputation. In the case of sugar, even small changes to the fill weight can cause costly inconsistencies as well as dissatisfaction among customers. A reliable automatic powder filling machine will most likely offer servo driven augers volumetric cups, or weigh filling systems as a means of furnishing precision.

Look for enhanced information provided by adjustable fill volumes, real-time feedback sensors, as well as interaction with checkweighers that eliminate underfilled and overfilled packages. These systems, even with various sugar types and diverse package configurations, uphold throughout control. This is critical for companies that package small sachets along with large bags, due to the differing levels of accuracy required for each format.

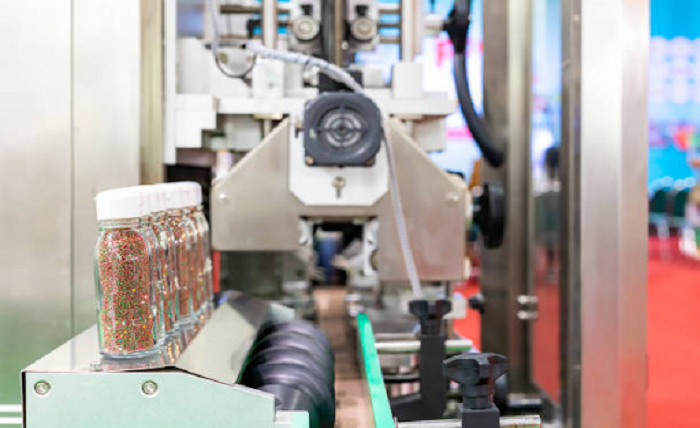

Modern machines are also required to maintain fill accuracy while handling various packaging styles, including pillow bags, stick packs, pouches, jars, and rigid containers. Modular components with programmable settings and quick changeover aids enable effortless switching between various packaging types. The appropriate automatic powder filling machine guarantees flexibility without compromising consistency, whether filling superfine icing sugar or coarse-grain raw sugar.

High Pacing and Consistent Output

Precision is as critical as speed in today’s marketplace. A properly engineered sugar packaging machine should achieve maximum output without sacrificing filling accuracy and hygiene standards. Fully automated machinery—which might be part of larger food manufacturing systems—can realize outputs between 30 to 120 packages per minute depending on the size and type of package.

When choosing a machine, think of options like continuous motion filling, multi-lane layouts, and rotary indexing features. These offer extremely short cycle times with increased output making them suitable for severe demand conditions. For example, an automatic powder filling machine equipped with high-speed servo controls, synchronized conveyors, and automated feeders operates at lowered productivity thresholds while reducing labor costs.

In addition, sophisticated machines with real time production tracking and automated production error diagnostics integrated further reduce human interface for non-interactive workflows. Labor efficiency multiplied while overall performance for long-running shifts on extended production was also sustained. Manufacturers can rely on stable and uninterrupted output with automatic bag positioning, no-product-no-fill sensors, and overload prevention features—critical for sustaining delivery timelines and operational seamlessness during high-workload production situations.

Real-Time Monitoring and Intelligent Controls

Manufacturing based on data has become essential in Industry 4.0. It is now possible to monitor sugar packaging machines in real-time. Problems can be diagnosed remotely, allowing operators to troubleshoot in a timely manner. The systems further aid in performance tuning considerations and recommendation of maintenance schedules alongside consistent operation.

Operator indifference is easily automated through touchscreen HMIs, recipe memory, and automatic calibration, enhancing productivity. Moreover, some machines permit interface with ERP or MES systems, allowing for total material and batch usage production traceability on a factory level.

Unplanned machine downtimes and wasteful processes could also be mitigated through the application of sensor-based sensory feedback loops, machine-learning algorithms, and predictive maintenance. By acquiring an automatic smart powder filling machine, a manufacturer does not only achieve operational capabilities but also benefits from the ongoing optimization capabilities embedded within the analytical systems of the machine.

Final Thoughts: Compliance and Performance Investment

In the context of sugar packaging machine selection, the decision goes beyond merely filling containers; it is shaping an overarching hygiene, speed, accuracy, and adaptable flexibility system for the long term. Automatic powder filling machines streamlined around these principles can cost-effectively optimize the packaging process.

In choosing a solution, consider your production goals, growth capacity, as well as industry compliances. If you are sachet packaging fine powdered sugar or pouch packaging bulk crystal sugar, the appropriate equipment can greatly minimize downtimes, product wastage, and inconsistencies in quality.

Most importantly, a sugar packaging machine of good quality and an automatic powder filling machine of high technological advancement guarantee proper handling, accurate filling, and fast throughput of sugar products a business can confidently rely on to meet their ever increasing demand.

Apart from operational standards, having the right equipment adds value to your brand. The consistency and good packaging of sugar products enhances corporate image and fosters trust and loyalty to the consumers. Corporate retail and industrial customers expect accuracy and beauty. This means the investment is not only reasonable but also well-designed considering the modern filing systems. In the modern world we live in, there are low profit margins and high consumer expectations, dependable packaging machinery has gone from being a luxury to a requirement.

Besides providing functional advantages, sophisticated sugar packaging solutions can act as a marketing differentiator. With features like tamper-evident seals, appealing pouches, or eco-friendly materials, the packaging class adds directly to brand equity. The addition of automated labeling and lot tracking also enhances traceability, a growing concern among health-oriented and regulatory-savvy consumers. Here, the choice of packaging machinery is not merely a matter of technology—it’s a strategic business decision that impacts all levels of the business, from the production line to retail displays.